Empowering Relationships: BVSM Marriage Services

Explore expert advice and support for successful marriages.

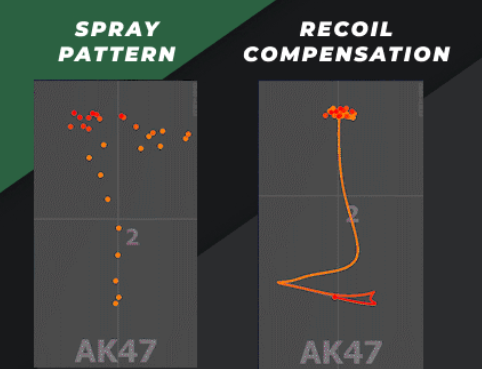

Tapping vs Spraying: What’s Your Aim Worth?

Discover the battle of tapping vs spraying! Find out which method delivers precision and value for your projects. Don't miss out!

Tapping vs Spraying: Understanding the Benefits and Drawbacks

Tapping and spraying are two popular techniques used in various industries, each offering distinct benefits and drawbacks. Tapping involves the direct application of a substance or material, allowing for precise control over the amount used. This method is often favored in situations where accuracy is critical, such as in mechanical applications or when dealing with sensitive chemicals. On the other hand, spraying enables a broader coverage area and can be more efficient for larger surfaces. Its ability to evenly distribute materials makes it ideal for tasks like painting or applying pesticides. However, while spraying can save time and labor, it may also lead to overspray and waste, particularly in smaller or intricate projects.

When deciding between tapping and spraying, it's essential to consider the specific requirements of the project. For instance, if fine detail and precision are paramount, tapping may be the superior choice. However, if speed and efficiency are more critical, spraying could prove advantageous. Ultimately, the choice should be guided by factors such as the desired outcome, the materials involved, and the environmental conditions. Understanding these benefits and drawbacks can help ensure that you select the most suitable method for your needs.

Counter-Strike is a popular first-person shooter game that emphasizes teamwork and strategy. Players can choose to be part of either the Terrorists or Counter-Terrorists, competing in various game modes. For those looking to improve their gameplay, adjusting rain settings can significantly enhance the in-game experience by optimizing graphics and performance.

Which Method Reigns Supreme: Tapping or Spraying in Targeted Applications?

When considering the best approach for targeted applications, the debate between tapping and spraying often arises. Tapping typically allows for more precision, enabling users to apply products directly to specific areas without overspray. This method is particularly valuable in scenarios where minimizing waste and maximizing efficacy are critical. Moreover, tapping is less likely to cause environmental concerns, as it limits the dispersion of materials into the surrounding area, making it suitable for indoor settings and sensitive locations.

On the other hand, spraying offers distinct advantages, particularly in terms of speed and coverage. When time is of the essence, spraying can cover large areas quickly, making it a preferred choice in agricultural applications or during large-scale project executions. However, this method may lead to less control over where the product lands, which can result in waste or unintended absorption in non-target areas. Ultimately, the choice between tapping and spraying will depend on the specific needs of the application, including desired precision, efficiency, and environmental considerations.

Is Your Aim Worth the Investment? A Deep Dive into Tapping vs Spraying Techniques

When considering whether tapping or spraying techniques are worth the investment, it's essential to evaluate the long-term benefits of each method. Tapping, which involves directly extracting substances from a source, can lead to higher quality results and a more controlled process. This method is particularly beneficial for those seeking precision and efficiency. On the other hand, spraying offers a broader coverage area and tends to be faster, making it a popular choice for larger projects. Here are some aspects to consider:

- Cost-effectiveness

- Time efficiency

- Quality of results

Investing in the right technique ultimately depends on your specific needs and goals. If your aim is to achieve optimal quality and maintain a high level of precision, tapping may justify the upfront cost. However, if speed and volume are critical, the spraying technique might yield a better return on investment. As you weigh your options, consider conducting a cost-benefit analysis to determine which method aligns best with your objectives and budget. In conclusion, the true worth of your investment in either technique lies in how well it meets your unique requirements.